Entendendo os purlins de aço: forças e aplicações principais

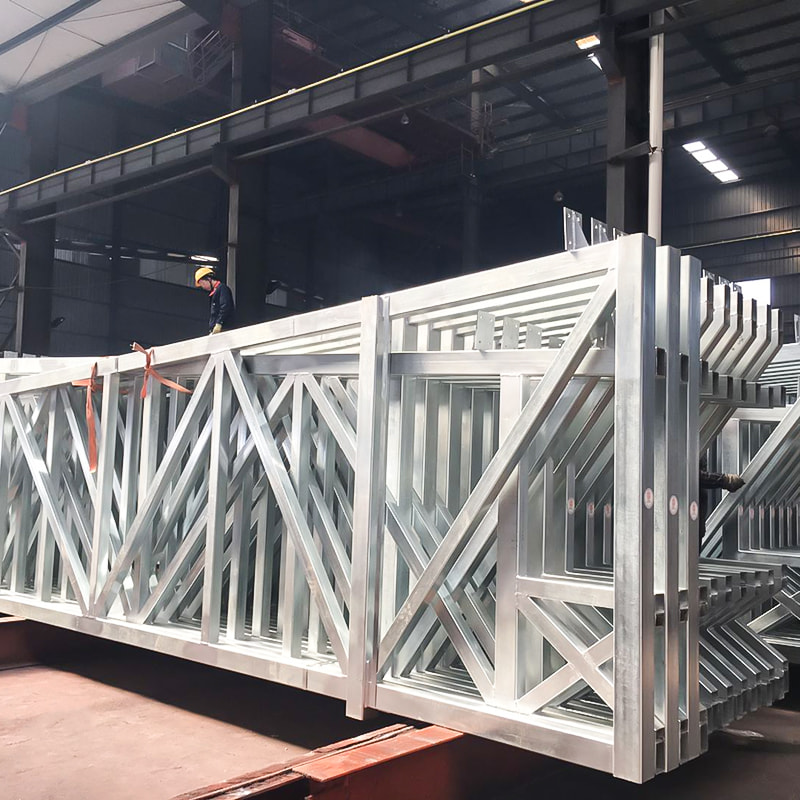

Fabricados a partir de aço formado a frio ou laminado a quente, os Purlins oferecem vantagens significativas, tornando-as a escolha dominante para muitas estruturas:

- Alta relação de força / peso: O aço fornece capacidade excepcional de carga em relação ao seu peso, permitindo vãos mais longos entre os quadros primários e reduzindo o aço estrutural geral necessário.

- Flexibilidade e consistência do design: Purlin de aço S são fora do local de engenharia de precisão, garantindo precisão e consistência dimensionais. Eles podem ser facilmente personalizados (seções c, z, u) para atender às necessidades específicas de carregamento e conexão.

- Velocidade da construção: Os purlinos pré-fabricados são leves e rápidos de instalar com conexões aparafusadas, acelerando a fase do envelope do edifício.

- Estabilidade dimensional: Ao contrário da madeira, o aço não deforma, encolhe ou torce com o tempo, mantendo a integridade estrutural e o alinhamento do revestimento.

- Eficiência e reciclabilidade do material: Os purlins de aço utilizam material com eficiência e são altamente recicláveis no final do ciclo de vida de um edifício.

Esses atributos tornam os purlins de aço excepcionalmente adequados para:

- Edifícios Industriais: Armazéns, fábricas, centros de distribuição (se beneficiam de vãos longos, interiores claros).

- Estruturas comerciais: Unidades de varejo, supermercados, escritórios, showrooms.

- Edifícios Agrícolas: Celeiros, galpões de armazenamento, alojamento de gado.

- Estruturas de grande porte: Hangares de aeronaves, salões esportivos, centros de exposição.

- ROTAFIT E MEZZANINE PISO: Fornecendo estruturas de suporte leves e fortes.

Considerações críticas: onde a adequação precisa de avaliação

Embora versátil, vários fatores determinam se os purlins de aço são a escolha ideal:

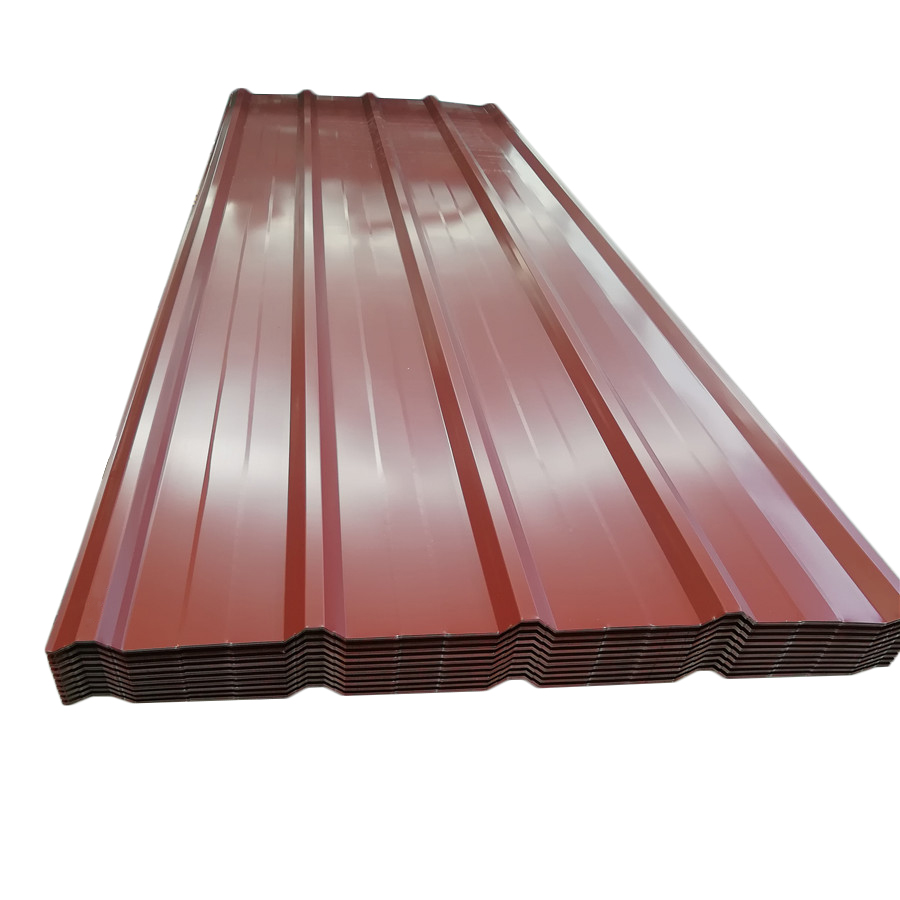

- Ambientes extremos corrosivos: Os purlinos de aço galvanizados padrão têm um bom desempenho na maioria das condições. No entanto, em ambientes altamente agressivos (por exemplo, plantas de processamento químico, áreas costeiras com spray de sal, certos contextos agrícolas com altos níveis de amônia), maior proteção contra corrosão (como revestimentos especializados ou graus de zinco mais alta) ou materiais alternativos (por exemplo, alumínio-galvanizado, polemente de fibra-reforço).

- Demandas arquitetônicas especializadas: Edifícios que requerem formas complexas e curvas de telhado ou geometrias altamente irregulares podem achar a natureza linear dos purlinos de aço padrão menos adequados do que os materiais que oferecem maior flexibilidade escultural (embora seja possível a fabricação especializada).

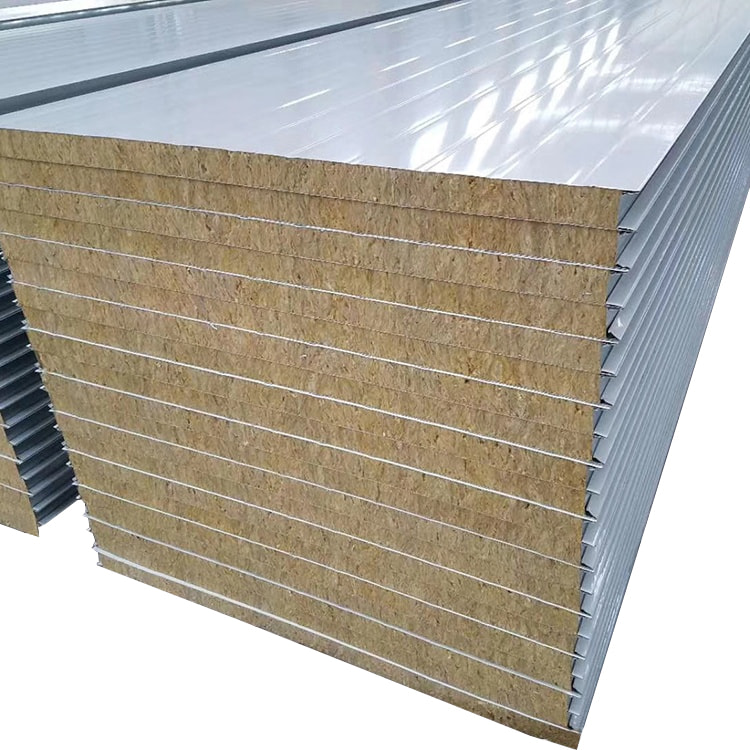

- Estruturas altamente isoladas e ponte térmica: O aço é um excelente condutor de calor. Nos edifícios que requerem desempenho térmico muito alto (por exemplo, padrões passivos da casa), os purlinos de aço podem criar pontes térmicas significativas, reduzindo o valor efetivo de isolamento se não for meticulosamente detalhado com quebras térmicas. Sistemas alternativos como madeira ou soluções compostos podem ser especificados para mitigar isso.

- Requisitos específicos de classificação de incêndio: Enquanto o aço tem um desempenho previsível em fogo quando protegido, alcançar classificações de incêndio muito altas apenas no nível de Purlin pode ser complexo e caro. O desempenho de incêndio do sistema estrutural geral (quadro primário, conexões, revestimento) é o fator governante, mas a seleção e proteção de purlin contribuem para a solução, exigindo engenharia cuidadosa.

- Casos de carga extrema: Embora forte, a seleção de Purlin é altamente dependente de cargas calculadas (mortas, vivas, vento, neve, sísmica). Em regiões com atividade sísmica excepcionalmente alta ou cargas de neve, o design do Purlin (seção, medidor, espaçamento, suporte) requer análise rigorosa de engenharia. O tipo de Purlin de aço (por exemplo, seções padrão versus seções construídas).

- Construção residencial: Os purlins de aço são cada vez mais utilizados em coberturas residenciais (especialmente para vãos maiores ou garagens anexadas), mas enfrentam competição de vigas/treliças tradicionais de madeira. Fatores como custo, preocupações de ponte térmica, desempenho acústico e familiaridade do construtor influenciam sua adoção em comparação com outros produtos de madeira engenhada nesse setor.

Tomando a decisão informada

Os purlins de aço são uma solução altamente eficiente, confiável e geralmente econômica para uma grande maioria dos tipos de construção comercial, industrial e de grande porte. Sua adequação depende de uma avaliação completa do projeto, considerando:

- Função de construção e vãos necessários: Requisitos de carregamento e recursos de span.

- Condições ambientais: Potencial de corrosão e proteção necessária.

- Objetivos de desempenho térmico: Abordando potencial ponte térmica.

- Requisitos de segurança contra incêndio: Integração na estratégia geral de proteção contra incêndio.

- Restrições orçamentárias: Equilibrando o custo inicial com a durabilidade do ciclo de vida.

- Projeto arquitetônico: Compatibilidade com a forma desejada.

Os purlinos de aço são um componente indispensável na construção moderna, oferecendo vantagens incomparáveis em resistência, eficiência e velocidade para uma ampla gama de tipos de construção. No entanto, rotulá -los universalmente adequados para todo A estrutura ignora fatores críticos específicos do projeto, como corrosão extrema, desempenho térmico especializado, formas arquitetônicas exclusivas ou demandas específicas de segurança contra incêndio. Uma análise cuidadosa de engenheiros e designers estruturais, pesando os pontos fortes dos purlinos de aço contra esses requisitos específicos do projeto e as alternativas potencialmente disponíveis, permanece essencial para determinar a solução estrutural ideal. Para a grande maioria das aplicações industriais, comerciais e de grande porte padrão, os purlins de aço representam uma escolha excelente e comprovada.